User Login

PRACTICAL & TACTICAL

ACCESSORIES

STAFF PICKS & GIFT IDEAS

SERVICES

INFORMATION

-

Welcome, Guest

- ( My Account | View Cart | Login )

(NOT CURRENTLY AVAILABLE)

Barbeque Set (Upswept Fillet, BBQ Knife, and Carving Fork) with Black G-10 |

|

| click to see more |

Fillet Knife (7 in) with Maple Burl (Semi-Stiff) |

|

| click to see more |

Fillet/Boning Knife (7-1/4 in.) with Black G-10 and FatCarbon (Semi-Stiff) |

|

| click to see more |

Fillet/Boning Knife (7-1/4 in.) with Maple Burl (Semi-Stiff) |

|

| click to see more |

Fillet/Boning Knife (7-1/4 in.) with Maple Burl (Semi-Stiff) |

|

| click to see more |

Fillet/Boning Knife (7-1/4 in.) with Maple Burl (Semi-Stiff) |

|

| click to see more |

Fillet/Boning Knife (7-1/4 in.) with Maple Burl (Semi-Stiff) |

|

| click to see more |

Fillet/Boning Knife (7-1/4 in.) with Maple Burl (Semi-Stiff) |

|

| click to see more |

Fillet/Boning Knife (7-1/4 in.) with Maple Burl (Semi-Stiff) |

|

| click to see more |

Fillet/Boning Knife (7-1/4 in.) with Masur Birch (Semi-Stiff) |

|

| click to see more |

Fillet/Boning Knife (7-1/4 in.) with Masur Birch (Semi-Stiff) |

|

| click to see more |

Upswept Fillet/Boning Knife (7 in.) with Maple Burl (Semi-Stiff) |

|

| click to see more |

Upswept Fillet/Boning Knife (7-1/4 in.) with Masur Birch (Semi-Stiff) |

|

| click to see more |

PRACTICAL & TACTICAL

ACCESSORIES

STAFF PICKS & GIFT IDEAS

SERVICES

INFORMATION

Featured Products

Of Knives And Men - Great Knifecrafters Of The World And Their Works by Francois-Xavier Salle

Sled Runner

Washington knifemaker Webb Hammond creates flint knapped knives that are true museum quality. This stunning display combines a sled runner artifact with Webb's expertly knapped custom knife. This knife was kept in a private collection since it was made. It is in brand new condition and by all appearances, Webb could have made it yesterday.

The white flint blade is hand knapped to a sharp edge. Webb used a traditional technique to hold the blade in place - black pitch. The handle ancient walrus ivory that is between 6000 and 9000 years old. Deep colors have leached into the ivory from surrounding soil over the centuries.

The knife is accompanied by a presentation stand. During the early to mid 1800s, Yupic Eskimos used ancient walrus ivory for a wide range of tools including fire starters, fishing weights, halibut hooks, and sled runners. A section of artifact Yupic sled runner is set on a wood base. Mounting holes and general shape from its former purpose as a sled runner are intact.

Exceptional work throughout!

Renaissance Wax (200ml)

Renaissance Wax is the #1 choice of major museums and art galleries for the preservation of the precious pieces.

Renaissance Wax is a revolutionary formula that is a semi-synthetic micro-crystalline fossil-origin wax entirely free of, damaging acids. It remains chemically neutral and is therefore completely safe, even on vulnerable surfaces.

Guard your precious pieces against the damaging effects of humidity, heat, dust, environmental destruction, aging, and ordinary wear. Renaissance Wax provides a barrier against fingerprints and the devastation of water, wine, alcohol and other spills. With its high moisture resistance, it forms a durable, lustrous protective coating. Prevents tarnish, corrosion and "bloom". Remains completely waterproof.

Flitz Metal Polish (150g)

Flitz is an excellent metal polish for carbon steel knives as well as fiberglass. This anti-tarnish formula lasts up to 6 months. It is non-abrasive, non-toxic, non-flammable, acid-free, won't dry out, and leaves behind no residue. Not designed for Damascus steel.

$22.95 DetailsRust Eraser (Sabitoru), Fine (320 grit)

This Rust Eraser nicely cleans and buffs away scratches & light surface rust on metal surfaces and more. 320 grit abrasive is suspended in a slightly "springy" rubber matrix, making it perfect for cleaning up slight imperfections on both curved and flat surfaces. The 320 grit Rust Eraser is very quick to remove rust and scratches and provides a clean looking satin finish. To clean up a surface faster, either start at the 46 grit Rust Eraser or the 120 grit Rust Eraser.. Measures approx. 2 3/4 inches x 1 1/2 inches x 1/3 inch.

Made in Japan.

Camellia Oil, 60ml (2 oz)

For centuries, camellia oil has been used to protect the finest Samurai swords. A small amount applied to your carbon steel knives will keep them free of corrosion and rust. Camellia oil is non-toxic and non-allergenic.

This spray bottle is a great size for professional chefs who want a bottle to carry in the knife bag.

Chef Steps Ceramic Rod and Cleaner

This set has everything you need to properly take care of your knives.

Ceramic rods provide the best touch up possible between sharpening. By removing very little material, the blade is honed to a razor edge. Fine ceramic rods will hone a knife to the most optimal edge. However, if a considerable time has passed since honing or sharpening, a coarse rod is often required. Generally, a ceramic rod should be approximately the length of the longest knife that you will be honing. This set comes with a 12 inch fine ceramic rod.

Over time, ceramic rods build up metal particles that clog the abrasive surface. The Superaser cleans the surface of all ceramic rods so that they will continue to hone just like they did when they were new.

MAC Kitchen Shears (KS-85) - 8-1/2 inch

I was really excited when the folks over at ChefSteps (www.ChefSteps.com) told me about their favorite kitchen shears. Their recommendations are always pretty spot on. (If you don't know about ChefSteps, go over and check them out!)

MAC's forged kitchen shears really get the job done. They will make quick work out of hard shellfish shells, poultry bones, fish bones, and miscellaneous packaging. One blade is micro-serrated for holding onto slippery surfaces while the other has a razor-polished edge that slices cleanly through tough shells and bones. The drop-forged stainless steel blades are some of the strongest we could find. They are held together by an adjustable nut with a quick-release joint so that you can maintain tight blade-to-blade contact and yet be easily taken apart for cleaning (very important in a kitchen shear!). Strong enough to cut through a penny, these shears were designed for heavy-duty kitchen tasks. Slightly right-handed handle but we know some lefties who use them too. These sharp and smooth functioning shears feature a blue textured/rubber grip.

Made in Japan.

Kai Fish Tweezers

Fish Bone Tweezers help effortlessly remove bones from fish.

- Used for removing bones from freshly filleted fish.

- Ideal for handling small, steaming hot objects that need to be delicately placed on the plate.

- Made in Japan from high quality stainless steel.

- Dishwasher safe.

These Fish Bone Tweezers are made by Kai, the maker of Shun Knives. The angled tweezer makes it very efficient. The ergonomic handle allows either a home user or a professional chef to effortlessly work for extended periods. This Japanese-made tool looks as great as it feels!.

Made in Japan.

Nano-Oil (10W8CC)

Nano Oil is our favorite lubricant for folder mechanisms. The 10 weight oil ensures smooth action instantly.

At under .090 micron in size, the active molecules of Nano-Oil are called Nano Bearings. They truly are within the nano scale technology. They are magnetically induced to adhere to microscopic crevices and actually penetrate metals, providing a very low friction, dynamic contact.

NanoLube formulations are compatible with most existing lubricants on the market today - both synthetic & mineral. The Nano-Bearings concentration level is such that adding a few drops to a common lubricant will dramatically improve its anti friction qualities.

The convenient needle applicator makes is easy to apply oil exactly where it is needed!

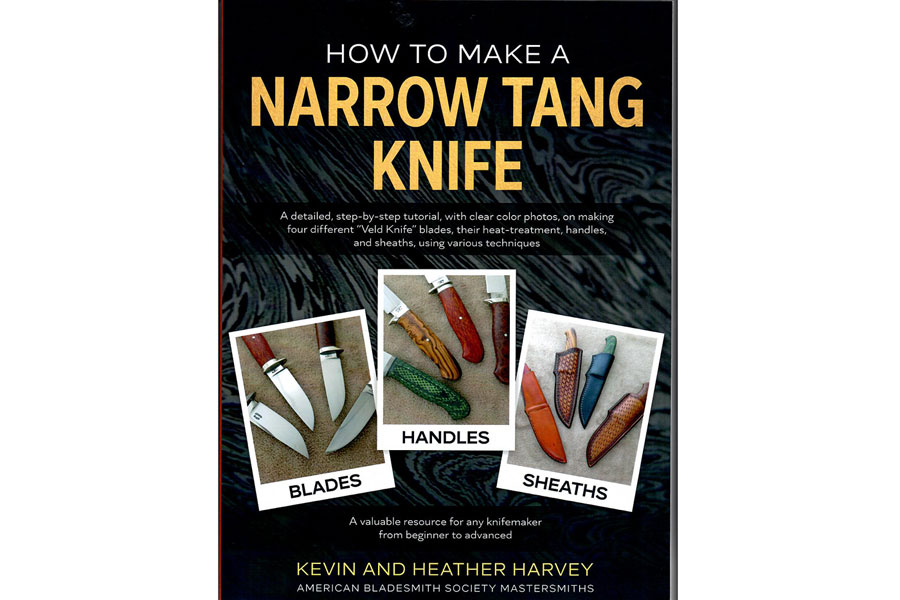

How To Make A Narrow Tang Knife

Beginning with making, heat treating, and sharpening a stock removal knife and moving into forging, forming the handle, and sewing the sheath, this exceptional manual is sure to help avoid many of the pitfalls that many knifemakers encounter as they begin their path. Even experienced knifemakers are sure to find different techniques that will improve their process and provide new approaches. How to Make a Narrow Tang Knife is sure to become a daily companion.

This book is signed by Kevin and Heather Harvey.

Mastersmiths Kevin and Heather Harvey have had a tremendous influence of forged South African custom knives. When I first met them in 1998 at the ABS Bladesmithing School in Old Washington, AR, it was clear that they arrived with exceptional talent and drive. What wasn't yet apparent was the number of bladesmiths that they would educate and inspire over the years to come. Rather than just returning to South Africa after our courses at the ABS school and proceeding to make their knives, they were immediately inspired to share the knowledge they gained.

They soon founded Heavin Forge and have taught countless bladesmiths from all over the world their techniques for knifemaking. Their style and methods are found in nearly every bladesmith coming out of South Africa today. Their devotion to sharing their knowledge has created a boon for knifemakers in and around Southern Africa.

When COVID19 began to spread in the spring of 2019, Heavin Forge needed to pivot. Their intimate classes would not be viable for several years to come. During this time, rather than simply ruminating, Kevin and Heather worked together to write and create this how-to manual. The photos and exceptionally detailed descriptions walk the reader through every step of making a knife. Having instructed thousands of students over 25 years at Heavin Forge and teaching at the ABS School, Mastersmiths Kevin and Heather understand the problems that beginning bladesmiths will encounter. This manual nicely catches those mistakes and explains each step in an easy-to-follow format.

- Publisher: Heavin Forge Media (July 13, 2022)

- Language: English

- Paperback: 272 pages

- ISBN-10: 0639714382

- ISBN-13: 978-0639714387

- Dimensions: 8.5 x 0.71 x 11 inches

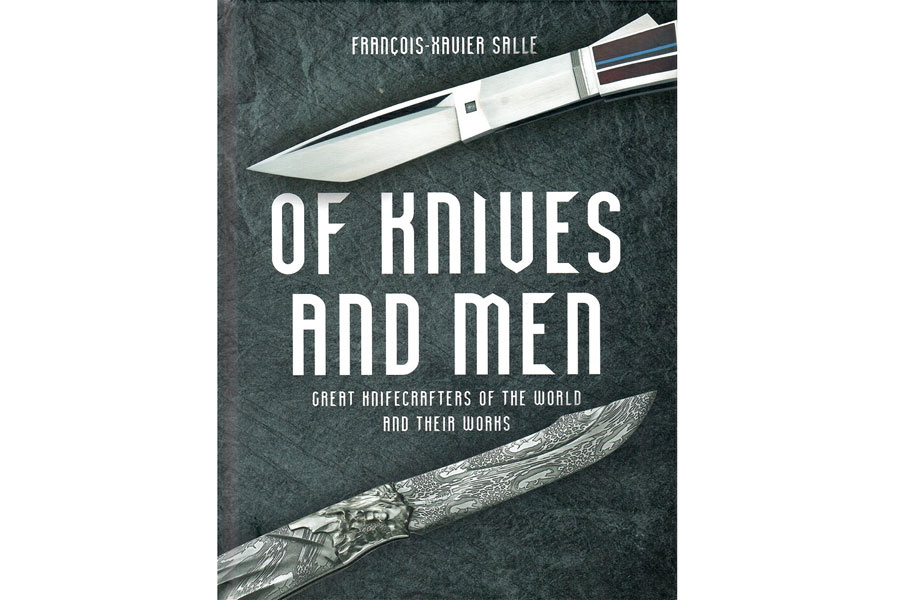

Of Knives And Men - Great Knifecrafters Of The World And Their Works by Francois-Xavier Salle

Of Knives and Men is a superb display of the world's foremost contemporary knifecrafters.

The 46 artisans and their works selected for this book are the most representative of the last 30 years. Each has their own style and character, mixed with utility and the knifemaking tradition of their home country and culture. Others are quite startling in their inventiveness: a simple steel knife with a handle made from a fox's lower jaw (Mickaël Moing, France); damascus steel blade and an ancient mammoth ivory handle (Pekka Tuominen, Finland); stainless steel blade with an ironwood handle encrusted with mother of pearl and precious stones (Harumi Hirayama, Japan); and a "button lock" knife of damascus steel, with a handle of damascus, gold, titanium and mother of pearl (Michael Walker, USA).

The knifemakers are from many countries -- Brazil, USA, France, Slovakia, Finland, Japan, Italy, Canada, South Africa and more -- displaying a stunning variety of materials and techniques.

There are 217 astounding knives and sheaths in all, plus a directory of decorative materials used for the handles and sheaths -- from birds eye maple to mammoth molar, carbon fiber and fossilized coral -- and techniques from ancient and lost-and-then-rediscovered to space age. All have a grade of cost and contact information for the makers. Extra sections on embellishments like scrimshaw, engraving and sculpting of handle material are added.

This is a unique and beautiful volume that will have very wide appeal.

- Publisher: Firefly Books (September 30, 2022)

- Language: English

- Hardcover: 240 pages

- ISBN-10: 0228104009

- ISBN-13: 978-0228104001

- Dimensions: 8.25 x 0.56 x 11 inches